Joining

Swaging

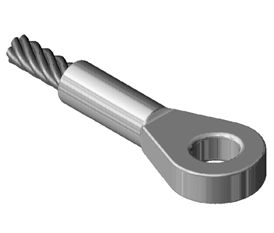

Swaging forms a mechanical interlock between components by forcing zinc into a softer material, such as a rubber hose, or by forcing it around irregular features, such as the strands of a steel cable. (see below) The cast fittings are normally cold-worked by tools that simultaneously apply forces in opposite directions and eliminate the need for a backup surface. Quantitative design data have yet to be developed for this type of application. Design is usually governed by previous experience and proved by test and development.

Rotary swaging forces the metal from the fitting around the strands of the steel cable forming a permanent connection that is stronger than the cable.